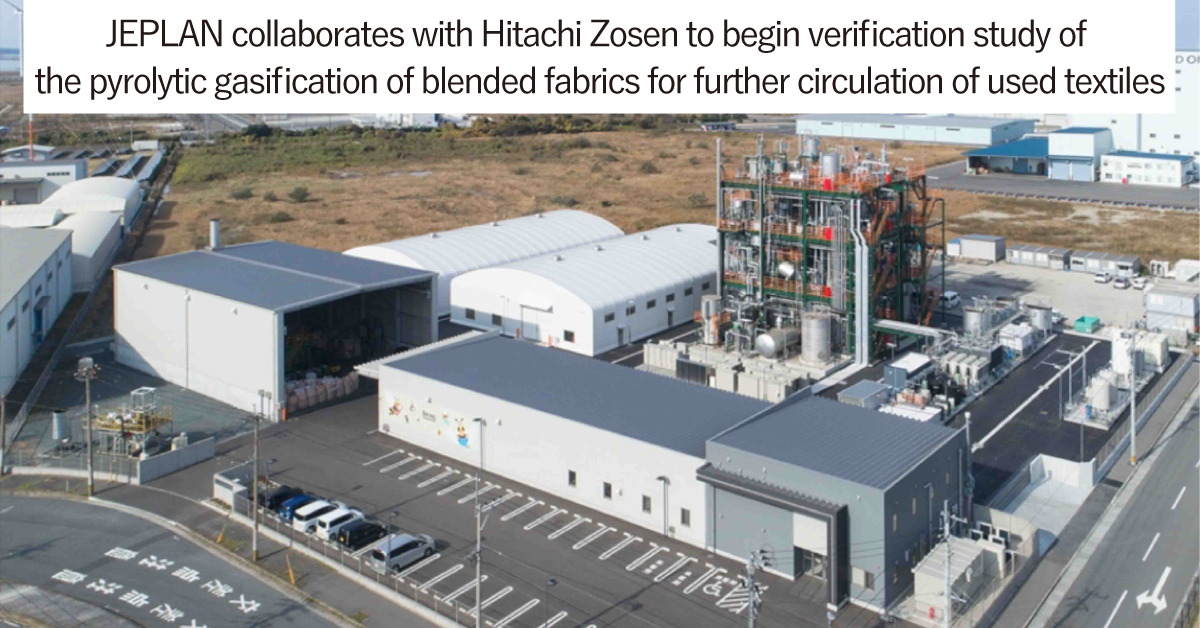

KITAKYUSHU HIBIKINADA PLANT

Reduces CO2 emissions by

49 %

*compared to petroleum-based polyester resin production

LCA of Kitakyushu Hibikinada Plant

Production capacity of polyester resins

1,000 t/year

T-shirt *250g per shirt

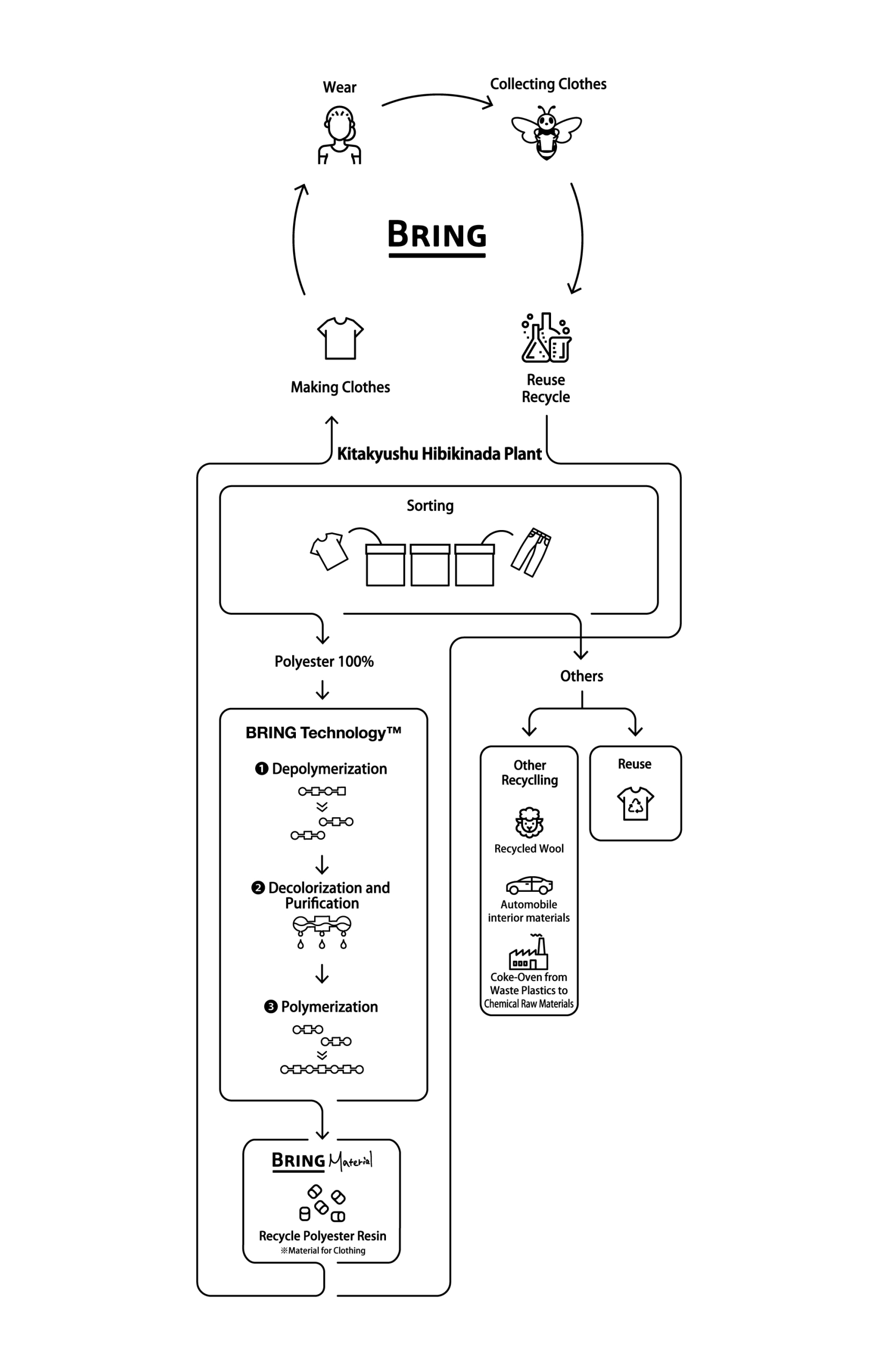

Utilizing the infinitely circulating our proprietary technology to…Recycle collected clothing and textile scraps into polyester resin

01 Sorting

02 Depolymerization

03 Decolorization and Purification

04 polymerization

Images

DATA

- Name

- KITAKYUSHU HIBIKINADA PLANT

- Location

- Kitakyushu-city, Fukuoka

- Completion

- 2017

- Raw materials

- Polyester fiber

- Products

- Recycled PET resin *Clothing application

- Process

- PET chemical recycling (BHET method)

- Capacity

- 1,000 t / year

- Site area

- 19,710m2

- Production Field

- Pilot plant / small-scale commercial plant

- Certification